babcock

Epoxy Resin for Floors has become one of the best alternatives for applications on different surfaces; giving the possibility of remodeling and creating beautiful epoxy floors with notable functional qualities; For this reason, the so-called liquid porcelain tile is positioned as one of the ideal raw materials to remodel our floor; and also due to its composition, it has been consolidating in industrial and commercial areas.

Do you know these types of flooring made with liquid porcelain tile?

In this article we will talk about everything you need to know about epoxy resin for floors; its advantages and disadvantages; on what surfaces they can be applied; and why decide to have an epoxy floor in your home, industry or business that provides safety, beauty and hygiene.

What is epoxy resin for floors? 🤔

When we talk about epoxy resin for floors we are referring to a thermostable liquid polymer; which hardens when mixed with a catalyst agent; and once dry, it leaves a completely smooth surface.

Epoxy resin for floors

Learn everything you need to know about epoxy resin for floors

With this liquid porcelain, highly resistant epoxy floors with a shiny appearance are manufactured.

But, what are the real advantages and disadvantages of this type of flooring?

Epoxy floor resin provides many qualities that place it above other types of flooring or remodeling materials.

Benefits of epoxy floors ✅

One of the greatest benefits offered by floors made with epoxy resin for floors is the excellent mechanical resistance they guarantee; even greater than concrete.

Liquid porcelain tile is capable of withstanding really heavy loads, approximately 6 thousand to 7 thousand tons per m².

Benefits of epoxy floors

Epoxy floors offer many benefits beyond a beautiful appearance

Additionally, due to its composition, epoxy creates a protective surface against chemicals, greases, oils and corrosive substances.

However, these are just some of the benefits that come from using epoxy resin for floors; Well, the advantages it offers are multiple.

Advantages of Liquid Porcelain 👨🎨

As we saw, the resistance that epoxy floors have is perhaps their greatest benefit to extend their application possibilities.

However, buying epoxy resin to manufacture or apply on floors is an excellent decision due to the advantages it guarantees. Take note!

✅ Durability

One of the characteristics that epoxy floors have is their long life, just like thick concrete, which exceeds any other type of floor.

For this reason, liquid porcelain tile is also known as High Traffic Epoxy Resin; since its surface is capable of withstanding continuous and heavy traffic.

Liquid porcelain and why to use it

Apply liquid porcelain tile to create highly resistant and durable floors

Because of this quality, epoxy resin for floors has become popular for industrial uses; since applied professionally they can last up to a decade without losing their qualities or resistance.

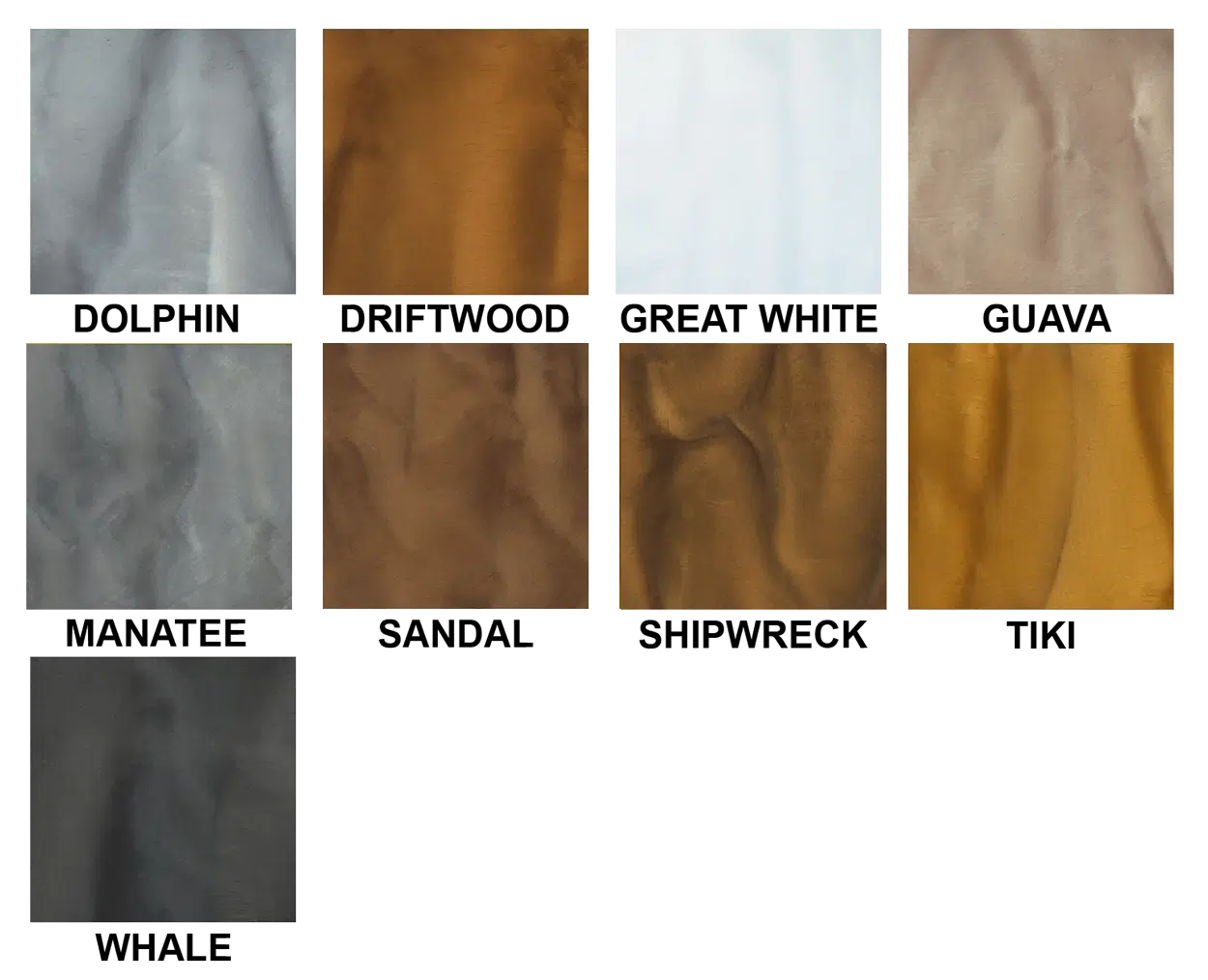

Epoxy floor resin leaves a seamless, smooth and shiny finish; In addition, liquid porcelain tile has a self-leveling quality, which enhances its aesthetic appearance.

Likewise, epoxy floors are scratch resistant; and if it suffers any type of damage, it can be repaired by applying resin to the site of the damage; once again achieving perfect uniformity on the surface.

✅ Liquid porcelain tile provides protection

Epoxy floors are capable of resisting corrosive attacks generated by certain substances; It is also resistant to water and any other type of humidity; They also provide protection against contaminants, deterioration and dirt.

Protective Epoxy Floors

Floors made with epoxy resin provide an excellent level of protection

In addition, liquid porcelain tile is usually covered with a thin non-slip coating; which makes epoxy floors totally safe; since it prevents any type of accidents related to displacements or transfers from occurring; and also, epoxy resin for floors that is resistant to high temperatures.

✅ Hygiene and Cleaning

Epoxy floors are easy to clean and do not require excessive or frequent maintenance; This is due to its high resistance to various substances, so only water and a mop will be enough to clean it.

Epoxy resin for high traffic floors

Floors with epoxy resin create a totally aseptic surface

In addition, epoxy resin for floors is recommended for environments that require total asepsis; that is, a set of methods applied to preserve sterility; for example, the use of liquid porcelain tile

What are epoxy floors and why are they relevant to the industry?

Epoxy floors are coatings that result from the combination of an epoxy resin with a hardener. These two components react chemically to form a rigid, strong and durable surface. In the industrial sector, where challenges such as wear and tear, chemical spills and heavy traffic are faced, these floors are essential to maintaining safe and efficient operations.

What are the main types of epoxy floors for the industry?

Self-leveling epoxy: Used for areas requiring a smooth, uniform surface. It is easy to clean and is ideal for pharmaceutical or food industries.

Epoxy mortar: It is the most resistant of all epoxy floors. It is used in industries that handle aggressive chemicals.

Non-slip epoxy: Incorporates aggregates that make the surface rough, ideal for areas prone to spills or wet places.

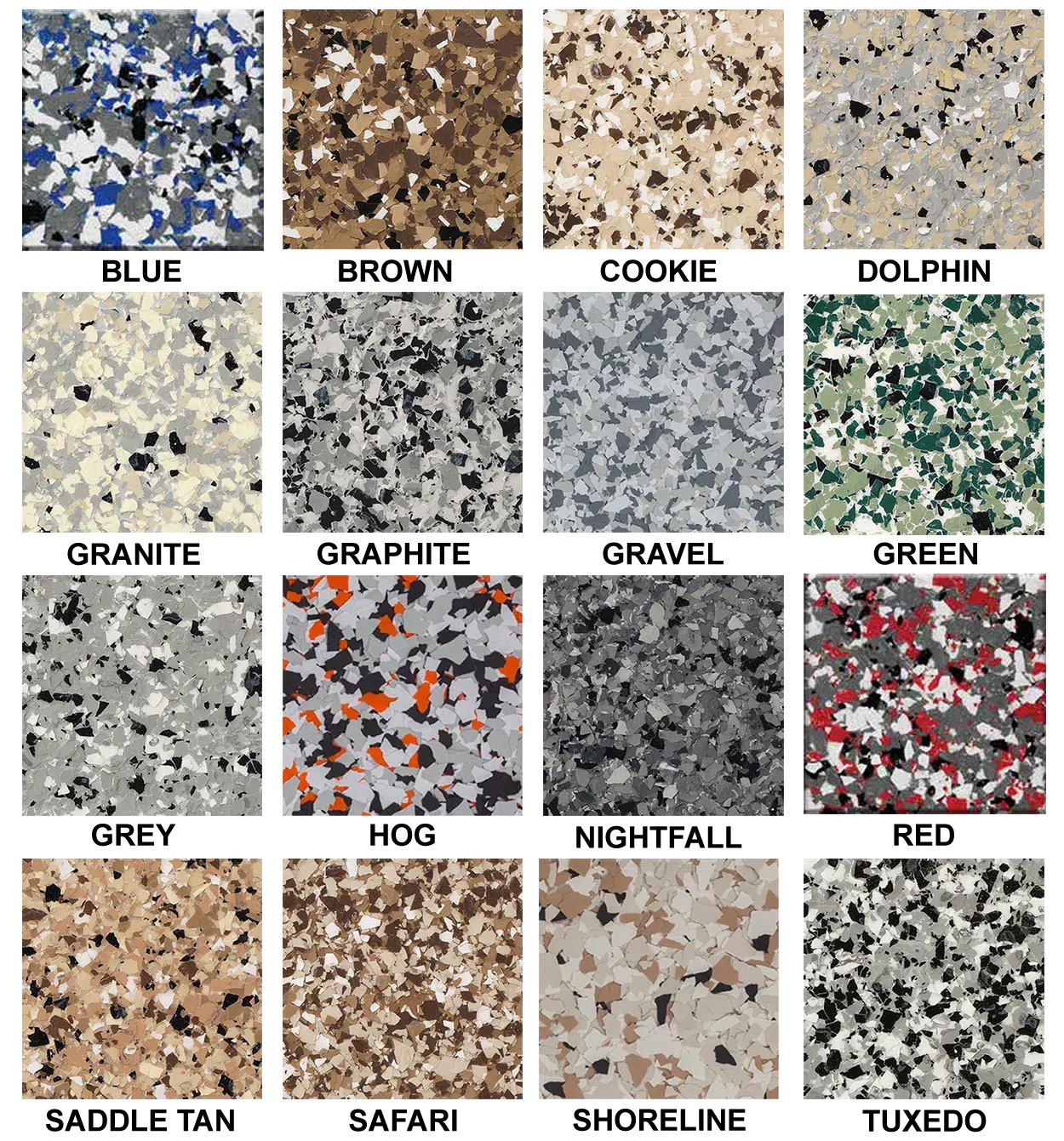

Flake Epoxy: Uses colored flakes that are spread over the surface for a decorative finish that is also durable.

How is epoxy applied to industrial floors?

Applying epoxy floors involves properly preparing the surface, making sure it is clean, dry and free of imperfections. Subsequently, the resin is mixed with the hardener and applied with rollers or spatulas. Depending on the type of epoxy, multiple coats and a specific curing time may be required.

What advantages do epoxy floors offer to industries?

Epoxy floors provide numerous benefits, such as:

Resistance to wear and heavy traffic.

Protection against chemical spills and stains.

Variety of aesthetic and functional finishes.

Ease of cleaning and maintenance.

Long useful life.

Epoxy floors in the industrial sector: the smart choice

The adoption of epoxy floors in the industry is a decision that combines aesthetics, functionality and durability. By choosing the right type for each need, you can ensure safe and efficient operations while maintaining a professional and modern appearance.

That's why here we bring you a step-by-step summary of how to make an epoxy floor. Check out! ✅

STEP 1: Evaluate the surface 🔎

Evaluating the soil will be the first thing we should do.

It is important to ensure that it is completely clean, dry, free of any moisture and unevenness or imperfections that are too large that the resin is not able to cover.

STEP 2: Make and apply the epoxy resin mixture 👩🎨

Once we have the liquid mixture previously ready (epoxy resin + catalyst in the proportions indicated by the manufacturer); It is applied to the surface with a rim or a special glass cleaner.

This is due to the amount necessary to obtain a completely perfect leveling, which generally ranges between 4 or 6 millimeters in thickness.

At this point it is important to highlight how much liquid porcelain tile covers; 1 liter of epoxy floor resin yields 1 m² at 1 millimeter thickness.

STEP 3: Level it and remove the bubbles 🧱

Subsequently, it is reviewed with a spiked roller, a simple tool but with great capacity to eliminate air bubbles; letting the material continue its process.

We can also use a “giant spatula”; or some tool that, without causing damage, allows us to spread the epoxy perfectly.

Epoxy resin for industrial floors

The finish of the liquid porcelain tile is smooth, non-slip, jointless and shiny.

In addition, scarifying shoes can be used to be able to walk on the already applied epoxy without problems and make the process easier.

STEP 4: Drying time for epoxy floors ⏳

Drying time will always vary depending on the manufacturer; Furthermore, we must be clear that this aspect will depend on 3 fundamental factors; from the surface on which it is applied; the temperature and humidity of the environment.

However, we can determine an estimated drying time between 48 and 72 hours.

Also, it is important to keep in mind that complete drying of epoxy floors is achieved after 5 days; and even a week.

After that period of time, the surface is ready to be walked on, place furniture, etc.

Final Recommendations for applying liquid porcelain 📝

After the drying time is over, a common mop will be enough to keep our floor clean and shiny.

If there is a spill or stain, we can use dry paper or a cloth damp with water and vinegar.

how to apply epoxy resin for floors

Always seek professional advice before doing an epoxy floor!

At first glance it seems simple, but the truth is that making an epoxy floor can be a bit cumbersome.

Therefore, it is emphasized that we always recommend requesting the services of a professional; They can make quotes, find quality suppliers and guarantee a perfect finish on our floors.

Epoxy resin for home floors 🏡

Among the different alternatives we have to cover the floor of our home; Epoxy resin for floors is the best option due to its benefits; in addition to its unbeatable quality, appearance, price and resistance.

And, although the application of liquid porcelain tile involves the creation of a completely new floor; It can also be applied to an existing floor.

Likewise, the smooth and seamless finish creates a feeling of spaciousness in the home.

Liquid porcelain for the home

Epoxy floors are a trend for home applications due to their variety of designs

Likewise, due to its waterproof and non-slip finish; Epoxy floors for the home have a greater variety of designs for the final, shiny and beautiful result.

Likewise, because epoxy floor resin does not crack and is resistant; It can be applied from the bedrooms to the living room, kitchen and bathrooms. Throughout the home!

Contact

- (312) 6362540

Address

Business Hours

| Mon: | 8:00 AM – 5:00 PM |

|---|---|

| Tue: | 8:00 AM – 5:00 PM |

| Wed: | 8:00 AM – 5:00 PM |

| Thu: | 8:00 AM – 5:00 PM |

| Fri: | 8:00 AM – 5:00 PM |

| Sat: | Closed |

| Sun: | Closed |

.jpeg)

Comments

Post a Comment